Potassium Pyrophosphate/TKPP: Content of each level

1. Introduction: Understanding The Versatile Chemical

Potassium Pyrophosphate (TKPP) is inorganic compound widely used in various industries and daily life. Whether it’s enhancing the brightness of electroplated layers, acting as an effective cleaning agent. or serving as a quality improver in food, potassium pyrophosphate demonstrates its powerful, “multi-faceted” capabilities.

| English Name | Potassium Phosphate (Tribasic/TKPP) |

| Chemical Formula | K₃PO₄ |

| Molecular Weight | 212.2663 g/mol |

| CAS Number | 7778-53-2 |

| Appearance | White crystalline powder |

| Density | 2.564 g/cm³ at 17°C |

| Melting Point | 1380°C |

| Solubility in Water | Very soluble, 90 g/100mL at 20°C |

| pH of Aqueous Solution | Strongly alkaline |

| Uses | Buffering agent, reagent in molecular biology, biochemistry, and chromatography |

2. Basic Information on Potassium Pyrophosphate: Structure, Properties, and Chemical Elegance

To understand the functions of potassium pyrophosphate, we must first grasp its chemical essence.

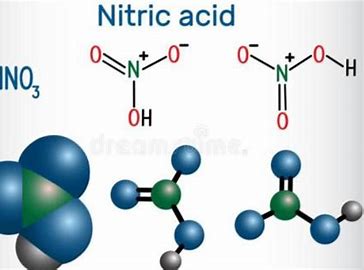

2.1 Structure and Properties: Exploring the Pyrophosphate Ion

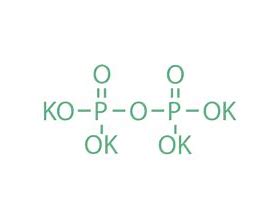

The core of potassium pyrophosphate lies in its unique pyrophosphate ion (P₂O₇⁴⁻).

- Chemical Bonding and Structural Characteristics: The pyrophosphate ion is formed by two phosphate groups bridged by an oxygen atom. creating a characteristic P-O-P bond. Although it generally exhibits a tetrahedral structure. the presence of the P-O-P bond introduces a certain degree of bending within the ion. Crucially, it possesses multiple sites capable of chelating metal ions.which is key to its role in electroplating bath stabilization and water treatment.

- Relationship with Related Acids (Pyrophosphoric Acid, H₄P₂O₇): Potassium pyrophosphate is a salt of pyrophosphoric acid. Pyrophosphoric acid itself is a moderately strong acid. but unlike orthophosphoric acid, it’s less stable in aqueous solutions and readily hydrolyzes into orthophosphoric acid.

Content of Phosphorus and Potassium in Potassium Pyrophosphate

K₄P₂O₇ is an important compound.and its chemical formula dictates the fixed proportion of phosphorus and potassium elements within it. Theoretically, potassium pyrophosphate contains approximately 42.45% potassium (K) and 19.98% phosphorus (P).

These precise elemental ratios allow it to function consistently as an electroplating bath stabilizer, a highly effective detergent builder, or a food quality improver, among other applications.

3.1 Quantitative Analysis: The Core Method for Ensuring Product Quality

- Titration Method: Economical and Efficient Routine Testing

- Principle: For example, under acidic conditions, the pyrophosphate ion will hydrolyze to orthophosphoric acid, allowing for its determination using a standard alkali solution. Alternatively, by leveraging its ability to chelate metal ions, EDTA complexometric titration of the metal ions can indirectly determine the potassium pyrophosphate content.

- Application: This method is relatively simple to operate and cost-effective, making it suitable for routine production quality control and quick, approximate content determination.

- Ion Chromatography (IC): Precise Separation and Detection

- Advantages: Ion chromatography is a high-precision analytical technique capable of efficiently separating and detecting pyrophosphate ions and other related phosphates (such as orthophosphates and tripolyphosphates) in solution. This not only provides a more accurate potassium pyrophosphate content but also crucial impurity information.

- Application: It’s suitable for testing high-purity products, research and development analysis, and detailed component analysis of complex chemical systems.

- Atomic Absorption Spectrometry (AAS) / Inductively Coupled Plasma-Optical Emission Spectrometry (ICP-OES): The Gold Standard for Potassium Content

- Principle: These two spectroscopic analytical techniques precisely quantify potassium content by measuring the absorption or emission intensity of potassium atoms in the sample at specific wavelengths.

3.2 Qualitative Analysis: Rapid Identification of Potassium Pyrophosphate

- Conventional Reagent Identification Methods: under specific conditions, potassium pyrophosphate can form characteristic complexes or precipitates with certain metal ions (such as copper or iron ions), allowing for its initial detection.

3.3 Content Range Analysis: The Significance of Potassium Pyrophosphate Content at 0.45-0.54

What does it mean when potassium pyrophosphate content falls within the range of 0.45-0.54?

- Possible Interpretations of this Value:

- Purity Range: This often indicates that the active ingredient content of the potassium pyrophosphate product is between 45% and 54%. This suggests the product is an industrial or specific application grade, not 100% pure, and may contain moisture, other phosphates, or by-products from the manufacturing process.

- Specific Formulation Ratio: In certain composite products (such as electroplating additives or complex detergents), potassium pyrophosphate may be a component of the formulation. In this context, the 0.45-0.54 value might refer to its mass fraction within the entire mixture, rather than its pure substance content.

- Impact of Different Content Levels on Product Performance and Application:

- Higher Purity: Generally implies better product performance stability and fewer impurity interferences. High-purity potassium pyrophosphate is suitable for applications requiring stringent purity, such as food-grade, pharmaceutical-grade products, or high-end electroplating processes.

- Lower Content: May contain more impurities or diluents, resulting in a relatively lower cost.

- Specific Proportions: In composite products, precise proportions ensure that potassium pyrophosphate performs its intended functions, such as providing appropriate chelating and buffering capabilities in detergents.

- Example 1 (Industrial Use): A company purchasing potassium pyrophosphate for a large-scale industrial cleaning solution might specify a “technical grade K₄P₂O₇ with 50% content.” This means that for every kilogram of product they buy, roughly 500 grams are pure potassium pyrophosphate, while the rest consists of water or other inert substances. This grade is typically cost-effective for applications where minor impurities don’t significantly impact performance.

- Example 2 (Cost-Effectiveness): A manufacturer producing a bulk detergent powder might choose a potassium pyrophosphate product with a 48% content. They’ve optimized their formula knowing that they’re paying for a certain percentage of non-active material, but the overall cost-benefit for their specific application makes it viable.

- Example (Electroplating Bath Additive): An electroplating company buys a “brightener additive” for their copper plating bath. The additive’s specification sheet might list “Potassium Pyrophosphate content: 0.50.” This doesn’t mean the K₄P₂O₇ they used to make the additive was only 50% pure. Instead, it means that pure potassium pyrophosphate makes up 50% of the total weight of that specific brightener additive, with other components (like organic brighteners, leveling agents, etc.) making up the remaining 50%. The value 0.50 (or 50%) here is a crucial part of the additive’s recipe.

4. Potassium Pyrophosphate Production Process: From Laboratory to Industrialization

The industrial production of potassium pyrophosphate is a complex and precise chemical engineering process.

4.1 Main Synthesis Route: The Dominance of Thermal Polymerization

Currently, the most common industrial method for producing potassium pyrophosphate is the Dipotassium Phosphate (K₂HPO₄) Thermal Polymerization Method.

- Principle: This method utilizes the property of dipotassium phosphate to undergo a dehydration condensation reaction at high temperatures. Its molecules link together, ultimately forming potassium pyrophosphate.

- Reaction Equation: 2K2HPO4heat

K4P2O7+H2O

- Process Description:

- Raw Material Preparation: High-purity dipotassium phosphate is selected as the starting material, which is fundamental for ensuring the quality of the final product.

- Thermal Polymerization: The pre-treated dipotassium phosphate is fed into specialized high-temperature reactors, such as rotary kilns or fluidized bed furnaces. Heating occurs under precisely controlled temperatures (typically between 350-500°C) and reaction times. During this process, water molecules from the dipotassium phosphate evaporate, and the molecules condense to gradually form potassium pyrophosphate.

- Cooling: After the reaction, the product needs to be rapidly cooled by a cooling device. This step is crucial to effectively prevent the product from re-absorbing moisture or undergoing adverse reverse reactions, thereby stabilizing product quality.

- Crushing and Screening: The cooled potassium pyrophosphate, usually in lump form, is mechanically crushed and then screened to obtain the desired particle size of potassium pyrophosphate powder.

- Key Process Parameter Control:

- Temperature: This is the most critical factor affecting reaction rate and product purity. Too low a temperature leads to incomplete reactions and low yields; too high a temperature can result in the formation of other phosphate by-products, or even product decomposition or discoloration.

- Time: Ensures sufficient reaction time for complete conversion of dipotassium phosphate, achieving the highest possible yield.

- Atmosphere: The reaction is typically carried out in air. However, to control product color, prevent oxidation, or meet specific purity requirements, it may sometimes be conducted under an inert atmosphere.

- Other Possible Production Methods:

- Reaction of Phosphoric Acid and Potassium Hydroxide: Another method involves directly reacting phosphoric acid with potassium hydroxide in specific molar ratios, followed by subsequent heating and dehydration steps to prepare potassium pyrophosphate. This method requires more stringent control over the phosphoric acid and potassium hydroxide ratios to ensure the formation of the desired product.

Yu Han Technology: Your Expert Partner in Potassium Pyrophosphate Production

At Yu Han Technology, we deeply understand that the quality of Potassium Pyrophosphate (K₄P₂O₇) directly impacts your product’s performance and market competitiveness in modern industry. We specialize in the R&D, production, and supply of potassium pyrophosphate, committed to being your most reliable partner.

Why Choose Yu Han Technology for Your Potassium Pyrophosphate?

Potassium pyrophosphate plant

- Expert Production, Exceptional Quality: We leverage advanced production processes and a stringent quality control system to ensure every batch of our potassium pyrophosphate products meets the highest industry standards. Whether it’s purity, solubility, or stability, we deliver quality you can trust.

- Broad Applications, Diverse Needs Met: Our potassium pyrophosphate products are widely used across various sectors, including electroplating, industrial cleaning, food processing, and detergents. As an efficient chelating agent, dispersant, buffering agent, or water softener, Yu Han Technology’s potassium pyrophosphate offers superior solutions for your specific applications.

Food additives factory

Leading Technology, Continuous Innovation: Yu Han Technology is deeply committed to advancing potassium pyrophosphate production technology. We consistently invest in R&D and optimize our production processes, aiming to provide you with products that are more efficient, environmentally friendly, and cost-effective.

Customized Services, Flexible Solutions: We understand that different clients may have unique requirements. Yu Han Technology offers flexible custom services, whether you need specific content, particle size, or packaging. We are dedicated to tailoring the most suitable potassium pyrophosphate product for you.

Choosing Yu Han Technology means choosing professionalism, quality, and a trustworthy long-term partner. We look forward to collaborating with you to build a brighter future together.