Sulfuric Acid Safe Storage and Measurement Guide

Sulfuric Acid (H2SO4) is a cornerstone chemical in countless industrial and laboratory processes. From fertilizer production to metal processing and battery manufacturing, its versatility is unmatched. However, this powerful substance demands respect. Improper storage and measurement of sulfuric acid can lead to severe hazards, including dangerous burns, equipment damage, and environmental contamination. This comprehensive guide will walk you through the essential best practices and safety precautions for sulfuric acid safe storage and accurate acid measurement.

The Dangers of Sulfuric Acid: Understanding the Risks

Before handling sulfuric acid, it’s crucial to understand the inherent risks associated with its properties:

- Corrosivity: Sulfuric acid is highly corrosive, readily attacking skin, eyes, mucous membranes, and other tissues. Direct contact can cause rapid and severe chemical burns, leading to permanent damage.

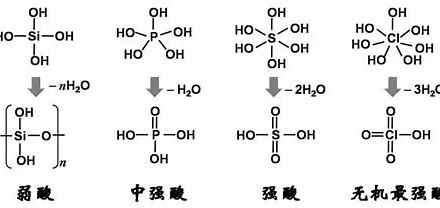

- Reactivity: This strong acid reacts vigorously with water, releasing significant heat. Always add acid to water slowly and with stirring to dissipate the heat. Adding water to concentrated sulfuric acid can cause violent splashing and even boiling. It also reacts with many metals, producing flammable hydrogen gas, which can create an explosion hazard.

- Dehydrating Properties: Sulfuric acid has a strong affinity for water and acts as a powerful dehydrating agent. When it comes into contact with organic materials like sugar or cellulose, it removes water molecules, generating heat and often resulting in charring.

- Toxicity: Inhaling sulfuric acid fumes or mist can irritate the respiratory system and cause serious lung damage. Long-term exposure to even low levels can have adverse health effects.

Safe Storage of Sulfuric Acid: Best Practices and Guidelines

Implementing proper storage procedures is paramount for preventing accidents and maintaining a safe working environment when dealing with sulfuric acid.

- Choosing the Right Storage Location: Select a well-ventilated area away from incompatible substances such as bases (e.g., sodium hydroxide), reactive metals (e.g., potassium, sodium), and organic materials. The storage area should be cool and dry to minimize pressure buildup and container degradation. Protect containers from direct sunlight and extreme temperature fluctuations. Clearly mark the storage area with prominent chemical safety warning signs indicating the presence of sulfuric acid. Ensure easy access to the storage area for emergency response personnel and spill containment equipment.

- Selecting Appropriate Storage Containers: Use containers specifically designed for acid storage. Suitable materials include certain grades of stainless steel (e.g., 304, 316), borosilicate glass, and specific grades of polyethylene (PE) and polypropylene (PP) that offer good chemical resistance to sulfuric acid. Always verify the compatibility of the container material with the concentration of sulfuric acid being stored. Ensure all containers are properly labeled with the full chemical name (Sulfuric Acid), concentration, hazard warnings (e.g., “CORROSIVE”), and date of receipt. Regularly inspect all storage containers for any signs of leaks, damage, or corrosion. Larger storage tanks should be equipped with appropriate venting mechanisms to prevent pressure buildup. You can find guidelines on selecting appropriate chemical storage containers from organizations like [External Link to a reputable chemical safety organization, e.g., OSHA].

- Secondary Containment: Implement secondary containment systems such as drip trays, bunds, or diked areas around storage containers to contain any potential spills. The secondary containment should have sufficient capacity to hold the volume of the largest container plus a percentage for potential rainfall or firefighting water.

- Segregation and Compatibility: Never store sulfuric acid near incompatible chemicals. Keep it separated from bases, oxidizing agents, reducing agents, and reactive metals. Refer to a chemical compatibility chart to ensure safe segregation. For example, storing sulfuric acid near sodium hydroxide could lead to a violent exothermic reaction.

- Handling Full and Empty Containers: Use appropriate equipment and procedures for safely lifting and transporting sulfuric acid containers. Even empty containers may retain residual sulfuric acid and should be handled with the same precautions and disposed of according to local and federal regulations. Consult the Safety Data Sheet (SDS) for specific disposal instructions.

Accurate Measurement of Sulfuric Acid: Techniques and Precautions

Accurate acid measurement is crucial for various applications, but safety must always be the top priority when handling sulfuric acid.

- Personal Protective Equipment (PPE) is Paramount: Always wear appropriate personal protective equipment (PPE), including chemical-resistant gloves (e.g., nitrile or neoprene), tight-fitting safety goggles, a full-face shield, and an acid-resistant apron or suit when handling or measuring sulfuric acid. Ensure the PPE is in good condition and fits properly. Refer to the SDS for specific PPE recommendations. You can learn more about selecting the right PPE for corrosive materials from resources like [External Link to a resource on chemical PPE].

- Choosing the Right Measurement Tools: Select appropriate glassware such as graduated cylinders and volumetric flasks made of materials resistant to sulfuric acid, such as borosilicate glass. Be aware that some plastics may not be suitable for concentrated sulfuric acid. For larger volumes or continuous monitoring, consider using specialized equipment like density meters or flow meters constructed with compatible materials.

- Safe Measurement Procedures: Always work in a well-ventilated area or under a properly functioning fume hood when measuring sulfuric acid. Pour the acid slowly and carefully to avoid splashing. Never add water directly to concentrated sulfuric acid. Instead, slowly add the acid to the water with constant stirring to dissipate the heat generated by the exothermic reaction. Use appropriate transfer devices such as siphons or pumps specifically designed for handling acids. Avoid direct contact with the sulfuric acid or its vapors. Ensure any prepared solutions are clearly and accurately labeled with the chemical name, concentration, and date.

- Calibration and Maintenance of Measurement Equipment: Regularly calibrate measurement equipment to ensure accurate readings. Clean and maintain measurement tools properly to prevent contamination and corrosion, which can affect accuracy and safety.

Emergency Procedures: Preparing for the Unexpected

Despite taking precautions, spills or accidental exposure can occur. Being prepared with well-defined emergency procedures is vital.

- Spill Response: In case of a sulfuric acid spill, immediately evacuate the area and notify emergency personnel. Contain the spill using appropriate spill control materials such as acid neutralizers (e.g., sodium bicarbonate, calcium carbonate) or absorbent pads. Clean up the spilled material safely and dispose of it according to environmental regulations. Refer to the SDS for specific spill response procedures.

- First Aid for Exposure:

- Skin Contact: Immediately flush the affected area with copious amounts of water for at least 15-20 minutes. Remove any contaminated clothing while flushing. Seek medical attention immediately.

- Eye Contact: Immediately flush the eyes with a continuous stream of water for at least 15-20 minutes, holding the eyelids open. Seek immediate medical attention. Ensure eyewash stations are readily accessible in areas where sulfuric acid is handled.

- Inhalation: Move the affected person to fresh air immediately. If breathing is difficult, administer oxygen if trained to do so. Seek medical attention.

- Ingestion: Do not induce vomiting. Rinse the mouth with water. Seek immediate medical attention.

- Emergency Equipment: Ensure the availability and proper functioning of emergency equipment such as safety showers and eyewash stations in areas where sulfuric acid is used or stored. Keep spill kits containing appropriate neutralizing agents and absorbent materials readily accessible. Ensure all personnel are trained on the location and proper use of this emergency equipment.

Regulatory Compliance and Further Resources

Handling and storing sulfuric acid are subject to various regulations. In the United States, the Occupational Safety and Health Administration (OSHA) provides guidelines and regulations for chemical safety in the workplace. Familiarize yourself with and adhere to all relevant local, state, and federal regulations. Always consult the Safety Data Sheet (SDS) for the specific concentration of sulfuric acid you are working with. The SDS contains detailed information on hazards, safe handling procedures, storage guidelines, and emergency response. You can typically find the SDS provided by the chemical supplier. For further information on sulfuric acid safe storage and handling, consult reputable organizations like [External Link to OSHA’s website on chemical safety] or [External Link to another reputable chemical safety resource].

Conclusion: Prioritizing Safety in Sulfuric Acid Handling

Safe handling of sulfuric acid requires a thorough understanding of its hazards and strict adherence to established safety protocols. Proper acid storage and accurate acid measurement, coupled with the consistent use of appropriate PPE and preparedness for emergencies, are essential for preventing accidents and ensuring a safe working environment. Remember that personal responsibility and comprehensive training are critical components of a robust chemical safety program. By prioritizing safety and following these guidelines, you can handle sulfuric acid effectively and responsibly.

Safety Data Sheet (SDS) Requirements

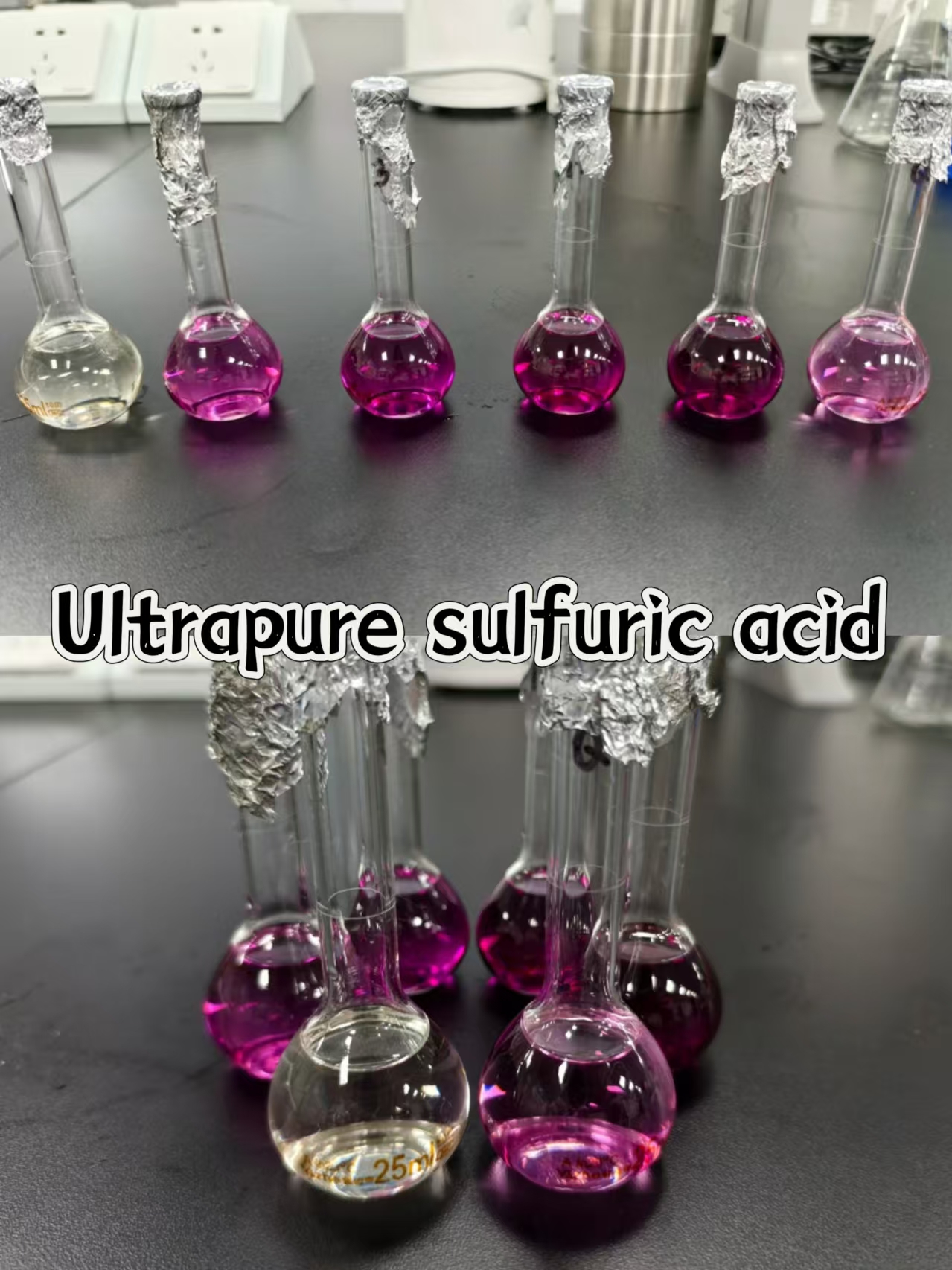

Sulfuric acid msds is a critical file. For details, you can refer to the specific parameters of Yuhan sulfuric acid, which tells you the physical, chemical, and toxicological characteristics of sulfuric acid.It also shows how to handle it safely, store it right, and what to do in emergencies. This helps lab workers stay safe and avoid risks when working with this dangerous chemical.You can also refer to other ultrapures.gerous chemical.

How to neutralize sulfuric acid ?

With Sodium Hydroxide: Sulfuric acid reacts with sodium hydroxide (NaOH) to form sodium sulfate and water. The reaction is: 2NaOH+H2SO4→Na2SO4+2H2O2NaOH+H2SO4→Na2SO4+2H2O.

With Sodium Thiosulfate: Mix sodium thiosulfate in phosphate buffer solution, adjust pH to 7.2-7.4, and sterilize at 121°C for 15 minutes.

Phosphate Buffer Solution: Used to adjust pH when neutralizing acids.

Glycine: Added to broth for neutralizing aldehyde-containing disinfectants.

Glutaraldehyde Neutralizer: Combine PBS, glycine, lecithin, and Tween 80 to neutralize 2% glutaraldehyde..

Tween 80: Used in broth to neutralize disinfectants with surfactants.

What are the safety considerations for storing sulfuric acid?

Container Selection: Use acid-resistant containers such as glass, plastic, or stainless steel, and avoid iron containers.

Sealing: Ensure containers are tightly sealed with rubber stoppers or seals to prevent evaporation and contamination.

Storage Conditions: Store in a dry, cool, and well-ventilated area, away from sources of fire and heat.

Personal Protection: Avoid direct contact; wear protective gloves, goggles, and a mask when handling.

Separate Storage: Do not store with other chemicals, especially flammable materials and oxidizers.

Clear Identification: Mark containers with “Sulfuric Acid” and hazard symbols, and clearly indicate storage locations.

Leak Prevention: In case of sulfuric acid spillage, use sand or other absorbing materials to contain and properly handle the spill.

Can the neutralized sulfuric acid be safely disposed of in street drains?

No, don’t throw neutralized sulfuric acid in street drains. We should handle and dispose of it in accordance with local regulations.This keeps our environment safe.

How can we accurately measure the concentration of sulfuric acid?

To find the exact concentration of sulfuric acid, we use lab tests. They help us make sure the acid is of the right quality.

What are the best practices for handling and disposing of sulfuric acid?

Handling sulfuric acid needs careful safety steps. Always wear the right protective gear and follow the Safety Data Sheet (SDS). When disposing of it, we must first neutralize the sulfuric acid and then adhere to local waste disposal regulations.

Contact us:https://www.yuhanchemi.com/products