H2SO4/Method for Producing Nitric Acid

Nitric acid (HNO₃) is essential across industries, serving as a key component in fertilizers, explosives, and pharmaceuticals. Understanding how it’s produced offers valuable insights into the backbone of modern industrial processes.

Overview of Nitric Acid Production

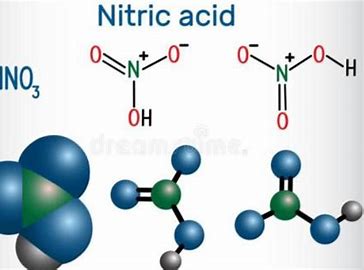

Nitric acid is a strong mineral acid with the formula HNO₃. Known for its highly corrosive nature, it is a clear, colorless liquid with a sharp, suffocating odor. Industries rely on it for extensive uses ranging from agriculture to manufacturing.

Chemical Properties of Nitric Acid

Nitric acid is often referred to as “aqua fortis,” meaning strong water. This compound consists of one nitrogen atom, three oxygen atoms, and one hydrogen atom. It has a molar mass of 63.01 g/mol and demonstrates strong oxidizing properties. In its pure form, the fluid appears colorless but can turn yellow due to nitric oxide gas dissolution. For more details on its chemical structure, visit Nitric Acid Overview.

Applications of Nitric Acid

This chemical powerhouse is a cornerstone of several industries:

- Agriculture: Used to produce ammonium nitrate fertilizers.

- Explosives: A critical component in manufacturing explosives like TNT and nitroglycerin.

- Pharmaceuticals: Plays a role in drug manufacturing and chemical synthesis.

To explore its wide applications, you can check out Nitric Acid Process.

The Ostwald Process

The Ostwald process, named after Wilhelm Ostwald, is the most common industrial method for producing nitric acid. It involves three main steps, which rely heavily on ammonia and oxygen.

Ammonia Oxidation

The process begins with ammonia (NH₃) being oxidized with oxygen (O₂) in the presence of a platinum-rhodium catalyst at temperatures of 850-900°C. This reaction produces nitric oxide (NO) and water (H₂O). The efficiency of this step ensures the process is economically viable.

For a detailed breakdown of this reaction, visit Ostwald Process – Principle.

Conversion to Nitrogen Dioxide

In the second step, nitric oxide reacts with oxygen to form nitrogen dioxide (NO₂). This is carried out under controlled conditions to ensure optimal conversion rates.

Absorption in Water

The final step involves dissolving nitrogen dioxide in water. This reaction produces nitric acid and regenerates nitric oxide, which is recycled to improve efficiency. These combined steps make the Ostwald process a pillar of modern nitric acid production.

For a full explanation of how these steps contribute to industrial production, see Ostwald Process – Wikipedia.

Alternative Methods of Production

While the Ostwald process is dominant, other methods can also create nitric acid.

Bubbling Nitrogen Dioxide into Water

This simple method uses nitrogen dioxide gas bubbled through water to form nitric acid. It’s primarily used in small-scale production. This approach doesn’t need the high-tech setups required by the Ostwald process but is less efficient. Learn more about this method in Make Nitric Acid – The Complete Guide.

High-Temperature Production Techniques

Some processes involve passing nitrogen and oxygen through electric arcs at extremely high temperatures. Though less common today, this method historically contributed to early nitric acid production.

Environmental and Safety Considerations

Producing nitric acid has environmental and safety challenges. Managing these is crucial to sustain its industrial importance.

Hazards of Nitric Acid Production

Nitric acid is highly corrosive and poses risks such as severe burns and respiratory damage. Workers must adhere to strict safety protocols, including protective wear and proper ventilation.

Environmental Impact and Regulations

The production process emits nitrogen oxides (NOₓ), greenhouse gases that contribute to pollution and climate change. Modern plants incorporate emission reduction technologies to minimize their environmental footprint. For more on regulations and emissions, visit Nitric Acid Production – EPA.

Conclusion

Understanding the methods for producing nitric acid, especially through the Ostwald process, highlights its significance in industrial applications. While alternative methods exist, the environmental and safety aspects underscore the need for careful management. As industries innovate, the focus remains on improving efficiency and reducing environmental impacts, ensuring this chemical continues driving progress.