How to Make Anhydrous Hydrofluoric Acid?

Hydrofluoric acid solution commonly has a concentration of 40%.

Commercially available hydrofluoric acid is mainly divided into industrial-grade and electronic-grade.

The concentrations of both are generally the same, but due to purity differences, their applications are different.

Industrial-grade hydrofluoric acid has relatively low purity and is suitable for applications such as metal pickling and glass etching.

Electronic-grade hydrofluoric acid has higher purity, usually reaching over 99.9%

and is widely used in semiconductor manufacturing and the production of other high-precision electronic components.

The density of the hydrofluoric acid solution changes with the increase of the solute mass fraction.

At the highest concentration (40% HF solution), its density is about 1.18 g/cm³, and this density value is applicable to both industrial-grade and electronic-grade hydrofluoric acid.

Hydrofluoric acid can be miscible with solvents such as water, alcohols, and ethers.

It is insoluble in organic solvents like benzene.

Hydrofluoric acid solution has high volatility.

The vapor pressure of a 40% HF solution is about 40 mmHg, and it can volatilize to form dangerous HF gas at room temperature.

So, special care is needed during its use and storage.

Anhydrous hydrofluoric acid is an important chemical raw material, which is widely used in many fields. The following is an introduction to its manufacturing methods:

Fluorite Method

- Raw Materials: Mainly concentrated sulfuric acid and fluorite (the effective component is CaF₂) and sulfur trioxide can also be used instead of sulfuric acid.

- Reaction Principle:

- When using concentrated sulfuric acid, the chemical reaction equation is CaF₂ + H₂SO₄ (concentrated) → CaSO₄ + 2HF↑, ∆H = -53.6 kJ.

- When using sulfur trioxide, the chemical reaction equation is CaF₂ + SO₃ + H₂O → CaSO₄ + 2HF↑.

- Production Process: Usually, a rotary kiln device is used.

- Under external heating conditions, fluorite reacts with sulfuric acid to roughly produce hydrogen fluoride, and then through purification processes such as condensation and distillation, impurities are removed to produce high-purity anhydrous hydrogen fluoride.

- In addition, some researchers have developed the production of hydrogen fluoride using a gas-liquid-solid fluidized bed reactor, which has a high mass transfer efficiency and is widely used in gas-solid, gas-liquid, or gas-liquid-solid catalytic or non-catalytic reactions.

Fluorosilicic Acid Method

- Raw Materials: Fluorosilicic acid (H₂SiF₆) and concentrated sulfuric acid with a mass fraction of 98wt%.

- Reaction Principle: H₂SiF₆ + H₂SO₄ (concentrated) → SiF₄ + 2HF↑ + H₂SO₄ (dilute).

- Production Process: Through processes such as concentration and dehydration of fluorosilicic acid, desorption of silicon tetrafluoride, and absorption of hydrogen fluoride, high-purity hydrogen fluoride with a mass fraction of 98wt% can be produced.

Ammonium Fluoride Intermediate Method

- Raw Materials: Fluorosilicic acid, which is a by-product in the phosphate fertilizer industry, is mainly used, supplemented with ammonia water, sodium fluoride, etc.

- Production Process: First, fluorosilicic acid is ammoniated to prepare ammonium fluoride and white carbon black.

- Then, ammonium fluoride and sodium fluoride react to prepare sodium hydrogen fluoride, and then sodium hydrogen fluoride is calcined at high temperature to prepare hydrofluoric acid. Finally, anhydrous hydrofluoric acid is obtained by distillation to remove impurities.

The following is a table of basic information about hydrofluoric acid:

| Information Category | English |

|---|---|

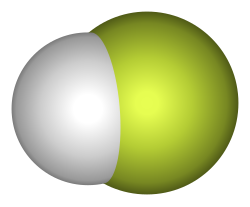

| Chemical Name | Hydrofluoric Acid |

| Chemical Formula | HF |

| Molecular Weight | 20.01 |

| CAS Registry Number | 7664-39-3 |

| EINECS Number | 231-634-8 |

| Physical State (at normal temperature and pressure) | Colorless, irritating odor gas |

| Melting Point | -83.36℃ |

| Boiling Point | 19.52℃ |

| Solubility in Water | Easily soluble in water |

| Density (at normal temperature and pressure) | 0.818 kg/m³ |

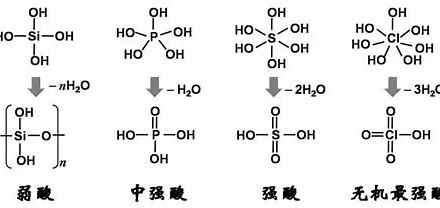

| Acidic Property | Weak acid in solution, dissociation equilibrium constant at room temperature is 6.3×10⁻⁴ (pKa = 3.17) |

| Corrosiveness | Strongly corrosive, can react with silicon dioxide and most metal elements |

| Toxicity | Toxic, contact with skin can cause burns, inhalation can cause bronchitis, pulmonary edema, etc. |

| Applications | Etching glass, manufacturing fluorides, organic synthesis, plastic industry, alkylation in refineries, etc. |

| Safety Description | S26 (In case of contact with eyes, rinse immediately and seek medical advice.), S36/37/37 (Wear suitable protective clothing, gloves and eye/face protection.), S45 (In case of accident or if you feel unwell, seek medical advice immediately (show the label whenever possible.)), S7/9 (Keep container tightly closed. Keep container in a well-ventilated place.) |

| Hazard Symbol | T+ (Very toxic), C (Corrosive) |

| Hazard Description | R26/27/28 (Very toxic by inhalation, in contact with skin and if swallowed.), R35 (Causes severe burns.) |

With the continuous development of technology, more efficient and environmentally friendly preparation processes may emerge in the future, promoting the continuous progress of the anhydrous hydrofluoric acid production industry.