How to Safely Transport Phosgene

Understanding Phosgene: Its Hazards

Before delving into transportation specifics, it’s vital to grasp the inherent dangers of phosgene. At room temperature, it’s a colorless gas, though it can appear as a liquid below 8.2°C. While often described as having an odor similar to freshly mown hay or corn, relying on scent for detection is dangerous due to olfactory fatigue, where your sense of smell can become dulled after prolonged exposure.

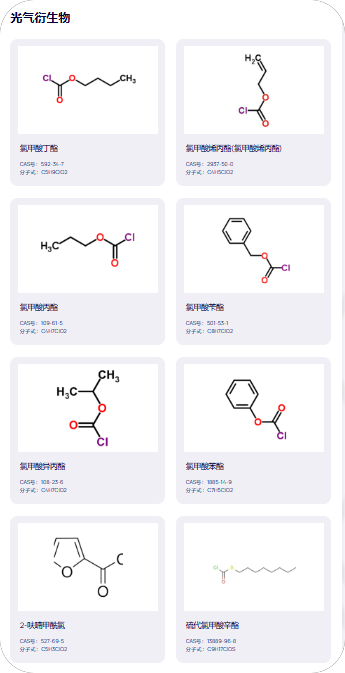

The primary concern with phosgene is its extreme toxicity. Even low concentrations inhaled can lead to severe and delayed pulmonary edema, a life-threatening condition where fluid accumulates in the lungs. It’s also highly corrosive, causing severe burns and frostbite upon skin or eye contact with the liquid form. Phosgene is heavier than air, meaning it can accumulate in low-lying areas, posing a hidden danger. Its reactivity with water, alcohols, and amines can also produce additional corrosive and toxic byproducts, such as hydrogen chloride.

Regulatory Framework for Phosgene Transportation

Internationally, key regulations include the UN Recommendations on the Transport of Dangerous Goods (Model Regulations), which provide a universal system for classifying, labeling, and documenting dangerous goods.

In the United States, the Department of Transportation (DOT) regulates hazardous material transport through 49 CFR Parts 100-185 (Hazardous Materials Regulations). Phosgene is classified under Hazard Class 2.3 (Toxic Gas), with a subsidiary hazard of 8 (Corrosive). Its proper shipping name is “Phosgene” and its UN Number is UN1076.

Essential Steps for Safe Phosgene Transportation

Executing the safe transport of phosgene requires meticulous attention to detail across several critical areas:

A. Packaging and Containers

Phosgene cylinders and ton containers must meet specific, stringent requirements. Leak-tight seals and valves are paramount to prevent any accidental release.

B. Labeling and Documentation

Clear and accurate labeling is non-negotiable. The proper shipping name (“Phosgene”) and UN Number (UN1076) must be clearly marked on all packages and on the shipping papers (e.g., Bill of Lading). Hazard labels and placards indicating both its primary hazard (Toxic Gas) . Safety Data Sheets (SDS), providing comprehensive information on hazards and safe handling, must always accompany shipments and be readily accessible to emergency responders.

C. Vehicle Requirements and Route Planning

Transport vehicles must ensure adequate ventilation. Phosgene containers must be properly segregated from incompatible materials to prevent dangerous reactions. Route planning is also critical, emphasizing the avoidance of densely populated areas, tunnels, and high-traffic zones to minimize public risk in case of an incident. Furthermore, robust security measures should be in place to prevent unauthorized access or tampering with the shipment.

D. Personnel Training and Certification

All personnel involved in the phosgene handling and transport chain must undergo comprehensive training. This includes understanding phosgene hazards, emergency procedures, and all relevant regulations. Regular competency assessments and specific training on how to respond to phosgene leaks or spills are absolutely essential. This expertise forms the backbone of chemical safety in transport.

Emergency Preparedness and Response

Even with the most stringent precautions, incidents can occur. Robust emergency response plans are therefore critical for the safe transport of phosgene.

A. Pre-Incident Planning

A detailed Emergency Response Plan (ERP) specific to phosgene incidents must be in place. This plan should include clear communication protocols with emergency services, and ensure the ready availability of necessary resources, such as specialized spill kits, appropriate Personal Protective Equipment (PPE), and first aid equipment.

B. Incident Response Procedures

In the event of a phosgene release, immediate actions are crucial: isolating the area, notifying emergency services, and, if safe to do so, attempting to stop the leak. Personnel must don full-face supplied-air respirators (SCBA) and chemical-resistant suits (e.g., Level A HAZMAT suits) before approaching the scene. For any exposure, immediate and thorough decontamination (flushing skin/eyes with copious amounts of water) and prompt medical attention for inhalation are vital. Spill containment should focus on preventing spread, and neutralization may involve ventilating to a scrubber system designed for phosgene.

C. Post-Incident Management

Following an incident, safe cleanup and decontamination of all affected materials are required. All incidents, regardless of severity, must be reported to the relevant regulatory authorities. Finally, a thorough investigation and review of the incident should be conducted to identify root causes and implement corrective actions, continuously improving future phosgene transportation safety.

Conclusion

The safe transport of phosgene is a testament to the rigorous demands of hazardous material transport. It requires unwavering adherence to regulations, meticulous attention to packaging and documentation, highly trained personnel, and robust emergency preparedness plans. Every stakeholder in the supply chain must commit to these principles to ensure the secure and responsible logistics of this critical, yet dangerous, chemical. Prioritizing safety and compliance is not just a regulatory obligation; it’s a moral imperative.

FAQ Section

- What are the main hazards of phosgene? Phosgene is extremely toxic by inhalation, causing severe and delayed pulmonary edema. It is also corrosive to skin and eyes and is heavier than air, posing a significant inhalation risk in low-lying areas.

- What regulatory bodies govern phosgene transportation? Internationally, the UN Recommendations on the Transport of Dangerous Goods, IMDG Code, and IATA Dangerous Goods Regulations are relevant. In the United States, the DOT (specifically 49 CFR) governs its transportation.

- What kind of PPE is required for handling phosgene? For direct handling or in emergency situations involving a leak, full-face supplied-air respirators (SCBA) and chemical-resistant suits (like Level A HAZMAT suits) are required. Regular handling requires appropriate chemical-resistant gloves, eye protection, and protective clothing.

- Can phosgene be transported by air? Due to its high toxicity, air transport of phosgene is extremely restricted and generally prohibited for commercial shipments, with very few exceptions for highly specialized purposes under strict conditions.

- What should I do in case of a phosgene leak during transport? Immediately isolate the area, notify emergency services, and, if safe to do so and properly equipped, attempt to stop the leak. Do not approach without appropriate PPE (SCBA and chemical-resistant suit). Refer to your specific Emergency Response Plan (ERP) and the Safety Data Sheet (SDS) for detailed instructions.