is stainless steel ok with sulfuric acid?

When working with sulfuric acid, choosing the right materials for storage and equipment is paramount for safety and longevity. Stainless steel is a common material in many industrial and laboratory settings, leading to the crucial question: is stainless steel ok with sulfuric acid? The answer, as with many chemical compatibility inquiries, is nuanced and depends heavily on several factors. This comprehensive guide will explore the interaction between sulfuric acid and various grades of stainless steel, providing you with the knowledge to make informed decisions.

Understanding Sulfuric Acid’s Corrosive Nature

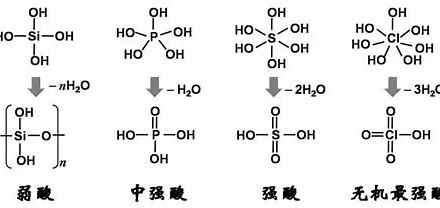

Sulfuric acid (H2SO4) is a highly corrosive mineral acid. Its corrosivity stems from several properties:

- Strong Acidity: It readily donates protons (H+), attacking many materials.

- Dehydrating Agent: Concentrated sulfuric acid strongly absorbs water, which can damage organic materials and even some metals.

- Oxidizing Agent (Concentrated): At high concentrations and temperatures, it can act as an oxidizing agent, further contributing to corrosion.

- Reducing Agent (Dilute): In lower concentrations and temperatures, it can act as a reducing agent.

These properties mean that the concentration and temperature of the sulfuric acid will significantly influence its interaction with stainless steel.

The Complex Relationship Between Stainless Steel and Sulfuric Acid

Stainless steel is an alloy known for its corrosion resistance, primarily due to the presence of chromium, which forms a passive oxide layer on the surface. However, this passive layer’s stability varies depending on the chemical environment, including the concentration and temperature of sulfuric acid.

General Trends:

- Concentration Dependence: The corrosion rate of stainless steel in sulfuric acid often shows a complex relationship with concentration. Some grades may exhibit better resistance at very low or very high concentrations, with increased corrosion at intermediate levels (around 20-80%).

- Temperature Sensitivity: Higher temperatures generally accelerate the corrosion rate of stainless steel in sulfuric acid across most concentrations.

- Grade Variation: Different grades of stainless steel have varying compositions (e.g., chromium, nickel, molybdenum content), which significantly impact their resistance to sulfuric acid.

How Different Stainless Steel Grades Fare with Sulfuric Acid

Not all stainless steels are created equal when it comes to sulfuric acid resistance. Here’s a look at some common grades:

- Type 304 Stainless Steel: This is a general-purpose grade with limited resistance to sulfuric acid. It may be acceptable for very dilute solutions (under 5%) at room temperature, but its corrosion rate increases rapidly with increasing concentration and temperature. Generally, 304 stainless steel is not recommended for most sulfuric acid applications.

- Type 316 and 316L Stainless Steel: The addition of molybdenum in these grades improves their corrosion resistance compared to 304. Type 316 stainless steel can offer useful service at room temperature with sulfuric acid concentrations below 15% and above 85%. However, it is susceptible to significant corrosion in the intermediate concentration range (20-80%), especially at elevated temperatures. The “L” designation indicates low carbon content, which helps prevent weld corrosion but doesn’t drastically improve sulfuric acid resistance.

- Type 317 Stainless Steel: With a higher molybdenum content than 316, Type 317 stainless steel offers slightly better resistance to sulfuric acid, particularly at lower concentrations and moderately elevated temperatures (up to around 65°C for concentrations up to 5%).

- Alloy 904L (UNS N08904): This is a super austenitic stainless steel specifically developed for excellent corrosion resistance in aggressive environments, including sulfuric acid across a wider range of concentrations and temperatures (up to around 35°C for the entire concentration range).

- Duplex Stainless Steels (e.g., 2205, 2507): These grades offer a mix of austenitic and ferritic structures, providing good strength and moderate corrosion resistance. Their resistance to sulfuric acid is generally comparable to or slightly better than 316 at lower concentrations and temperatures (below 60°C for concentrations up to 40% for 2205).

- High-Alloy Stainless Steels (e.g., Alloy 20, Hastelloy alloys): For more aggressive sulfuric acid environments (higher concentrations and temperatures), specialized high-alloy stainless steels or nickel-based alloys like Alloy 20 and Hastelloy are often necessary. These materials offer superior resistance but come at a higher cost.

Factors to Consider When Using Stainless Steel with Sulfuric Acid

When evaluating the suitability of stainless steel for sulfuric acid applications, consider these critical factors:

- Sulfuric Acid Concentration: This is the most significant factor. Refer to corrosion charts and material compatibility guides for specific grades at your intended concentration.

- Operating Temperature: Even grades with good resistance at room temperature may corrode rapidly at elevated temperatures.

- Flow Velocity: High flow rates can erode the passive layer on stainless steel, increasing corrosion, especially in turbulent conditions.

- Impurities: The presence of other chemicals, such as chlorides, can significantly increase the corrosivity of sulfuric acid towards stainless steel.

- Aeration: The presence of oxygen (aeration) can sometimes increase or decrease the corrosion rate depending on the stainless steel grade and acid concentration.

- Service Life Requirements: The acceptable corrosion rate will depend on the intended lifespan of the equipment.

Best Practices for Using Stainless Steel with Sulfuric Acid

If stainless steel is deemed suitable for your specific sulfuric acid application:

- Choose the Right Grade: Select a stainless steel grade known for its resistance to sulfuric acid at your specific concentration and temperature. Alloy 316L is a common minimum recommendation for some dilute applications, but higher alloys like 904L or specialized alloys may be necessary for more aggressive conditions.

- Consult Material Compatibility Charts: Always refer to reliable material compatibility charts and corrosion data specific to sulfuric acid and different stainless steel grades. Many reputable material suppliers provide this information.

- Consider Testing: For critical applications, consider conducting corrosion tests under your specific operating conditions to verify material suitability.

- Implement Proper Design: Design systems to minimize turbulence and stagnant areas where corrosion can be accelerated.

- Regular Inspection and Maintenance: Implement a regular inspection and maintenance program to detect any signs of corrosion early.

Alternatives to Stainless Steel for Sulfuric Acid

In many cases, especially with higher concentrations and temperatures, other materials may be more suitable for sulfuric acid storage and handling, including:

- Carbon Steel: Surprisingly, carbon steel can be suitable for highly concentrated sulfuric acid (above 80-90%) at ambient temperatures and low flow rates, as a protective iron sulfate layer can form. However, it’s not suitable for dilute or mid-range concentrations.

- Glass and Glass-Lined Steel: Offer excellent resistance to most concentrations of sulfuric acid but are fragile and susceptible to mechanical damage.

- Fluoroplastics (e.g., PTFE, PFA): Exhibit excellent chemical resistance to sulfuric acid across a wide range of concentrations and temperatures but may have limitations in terms of mechanical strength and temperature resistance compared to metals.

- High-Silicon Cast Iron: Offers good resistance to all concentrations of sulfuric acid up to boiling points but is brittle and difficult to fabricate.

Conclusion: Choosing Wisely for Sulfuric Acid Compatibility

So, is stainless steel ok with sulfuric acid? The answer is a qualified “sometimes,” heavily dependent on the specific grade of stainless steel, the concentration and temperature of the sulfuric acid, and other operating conditions. While some grades like 316L may be acceptable for limited applications with dilute or highly concentrated acid at room temperature, more aggressive conditions often require higher-alloy stainless steels or alternative materials. Always prioritize safety and consult reliable material compatibility data and experts when selecting materials for sulfuric acid storage and handling.

Key Takeaways:

- Type 304 stainless steel generally has poor resistance to most sulfuric acid concentrations.

- Type 316 and 316L stainless steel offer better resistance but are vulnerable in mid-range concentrations and at higher temperatures.

- Specialized stainless steel grades like 904L offer superior resistance.

- Consider factors like concentration, temperature, flow velocity, and impurities.

- Always consult material compatibility charts and consider alternatives like carbon steel, glass, or fluoroplastics.

FAQs (Frequently Asked Questions)

Is stainless steel compatible with sulfuric acid?

Stainless steel’s corrosion resistance to sulfuric acid depends on the steel grade, acid concentration, and temperature.Understanding these factors is crucial for industrial applications.

What are the effects of concentration and temperature on sulfuric acid’s corrosiveness?

The corrosiveness of sulfuric acid increases with higher concentrations and temperatures. Low concentrations (<15%) may be less damaging, while high concentrations (>85%) pose significant risks to stainless steel. Intermediate concentrations (15%-85%) can also be particularly harmful.

Which grades of stainless steel are most resistant to sulfuric acid corrosion?

Grades like 304, 316, duplex steels, and 904L stainless steel offer different resistance levels to sulfuric acid. Each has limits for dilute acids and maximum concentrations to avoid.

How does temperature affect corrosion rates with sulfuric acid?

Temperature plays a critical role in the corrosive effects of sulfuric acid. Higher temperatures can speed up corrosion, so it’s important to set safe storage and processing temperatures to reduce the risks.

What alloying elements enhance stainless steel’s resistance to sulfuric acid?

Alloying elements such as molybdenum and copper significantly improve the corrosion resistance of stainless steel against sulfuric acid. Their presence helps mitigate the adverse effects caused by exposure to this aggressive chemical.

What are best practices for selecting materials when handling sulfuric acid?

When working with sulfuric acid, it’s important to select appropriate materials based on concentration and temperature. Recommended alternatives include high-silicon cast iron, which offers better durability and reduced maintenance needs in industrial applications.

Yuhan Chemical provides various sulfuric acids in various concentration levels. If you have any needs, please contact:https://www.yuhanchemi.com/ultra-pure-sulfuric-acid

Yuhan Chemical, focusing on chemical raw materials:https://www.yuhanchemi.com/about-us