| parameter | um | minimum | utmost | |

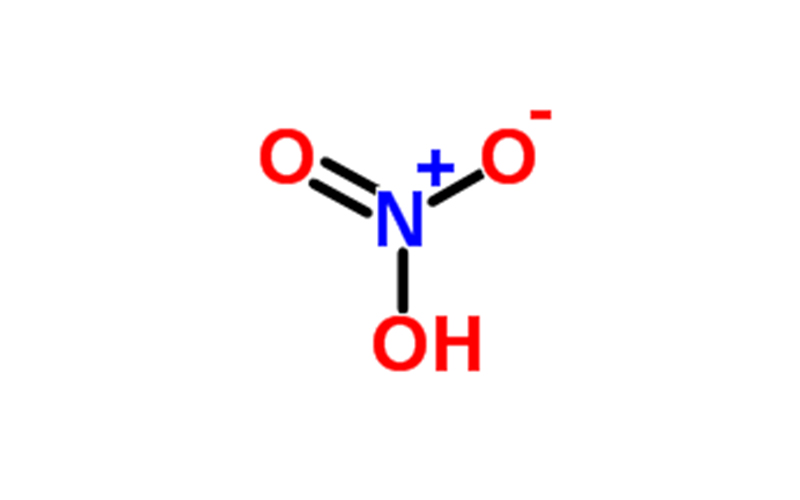

| Assay (HNO3) | % | 69.0 | 70.0 | |

| color | APHA’s | 5 | ||

| Chloride (Cl) | ppb | 80 | ||

| Phosphate (PO4) | ppb | 50 | ||

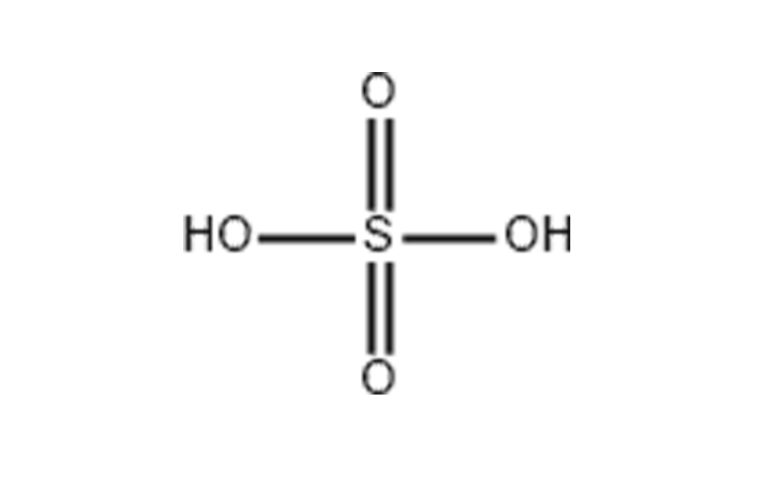

| Sulfate (SO4) | ppb | 100 | ||

| The impurities are the greatest | um | minimum | utmost | |

| Aluminum (Al) | ppb | 0.05 | ||

| Antimony (Sb) | ppb | 0.05 | ||

| Arsenic (As) | ppb | 0.05 | ||

| Barium (Ba) | ppb | 0.05 | ||

| Beryllium (BE) | ppb | 0.05 | ||

| Bismuth (Bi) | ppb | 0.05 | ||

| Boron (B) | ppb | 0.05 | ||

| Cadmium (Cd) | ppb | 0.05 | ||

| Calcium (Ca) | ppb | 0.05 | ||

| Chromium (Cr) | ppb | 0.05 | ||

| Cobalt (Co) | ppb | 0.05 | ||

| Copper (Cu) | ppb | 0.05 | ||

| Gallium (Ga) | ppb | 0.05 | ||

| Germanium (Ge) | ppb | 0.05 | ||

| Gold (AU) | ppb | 0.05 | ||

| Iron (iron) | ppb | 0.05 | ||

| Lead (Pb) | ppb | 0.05 | ||

| Lithium (Li) | ppb | 0.05 | ||

| Magnesium (Mg) | ppb | 0.05 | ||

| Manganese (Mn) | ppb | 0.05 | ||

| Molybdenum (Mo) | ppb | 0.05 | ||

| Nickel (Ni) | ppb | 0.05 | ||

| Niobium (Nb) | ppb | 0.05 | ||

| Potassium (K) | ppb | 0.05 | ||

| Selenium (Se) | ppb | 0.05 | ||

| Silver (Ag) | ppb | 0.05 | ||

| Sodium (Na) | ppb | 0.05 | ||

| Strontium (Sr) | ppb | 0.05 | ||

| Tantalum (Ta) | ppb | 0.05 | ||

| Thallium (Tl) | ppb | 0.05 | ||

| Tin (Sn) | ppb | 0.05 | ||

| Titanium (Ti) | ppb | 0.05 | ||

| Tungsten (W) | ppb | 0.05 | ||

| Vanadium (V) | ppb | 0.05 | ||

| Zinc (Zn) | ppb | 0.05 | ||

| Zirconium (Zr) | ppb | 0.05 | ||

| Particle counting | um | minimum | utmost | |

| ≧ 0.1 μm | pcs/ml | 300 | ||

| ≧ 0.5 microns | pcs/ml | 50 | ||

| ≧ 1.0 microns | pcs/ml | 10 | ||

Physical and chemical properties

- Density: ~1.41 g/cm³ (at 20°C)

- Boiling point: ~83°C

- Melting point: -42°C

- pH: Strong acidity

- Solubility: Completely miscible with water, reacts violently with organic solvents

- Decomposition: Releases NO₂ gas when heated or exposed to light

- Synonyms: nitric acid; fuming nitric acid; hydrogen nitrogen water; concentrated nitric acid; dilute nitric acid; nitrate water; hydrogen nitrate; Nitric acid, 0.1N standard solution; Nitric acid standard solution

In R&D and production, it is often necessary to analyze the content of various elements in samples, and AA, ICP-OES, ICP-MS is usually used to analyze the elements of samples dissolved in ultra-pure reagents:

1. Analyze the metal elements in the sample by signal absorption spectroscopy, suitable for G1/G2 grade products.

2. Spectral analysis of metal elements in plasma samples, applicable to G3/G4 grade products – ppb grade.

3. Analyze the metal elements in plasma samples by mass spectrometry, and apply G5/G6 grade products – ppt grade.

Wrap:

Imported high-purity, corrosion-resistant fluoropolymeric resin PFA material is used as the packaging container for G4, G5 and G6 series products;

Use high-density polyethylene bottle (HDPE) as the packaging material of G1~G3 series products;

The 500mL packaging products are secondary packaged in PE bags, and the outer layer of PET bottles is protected to improve the safety of the products during transportation.

Other ultra-pure reagents can be customized, and detailed needs can be contacted by our salesman to communicate specifications

Main applications:

- Semiconductor industry:

- Wafer cleaning and etching processes are essential

- For RCA cleaning (SC-2) to remove metal contaminants

- Electronics Manufacturing:

- High-purity oxidizers in the production of circuit boards and components

- Etchants in microfabrication and lithography

- Chemical Synthesis & Research:

- Reagents in high-purity chemistry and drug synthesis

- Precursor of nitrification reactions

- Metallurgy & Surface Treatment:

- For the passivation of stainless steel

- High-purity nitric acid for metal etching and refining

- Environmental & Analytical Applications:

- Used in ICP-MS and other trace analysis techniques

- For ultrapure water production

Safety and handling

- Hazards: Strong acids and oxidants, highly corrosive to metals and skin, emitting toxic NOx fumes when decomposed.

- Storage:

- Store in an acid-resistant, airtight container (e.g., PTFE, PFA, or glass)

- Store in a cool, dark, well-ventilated place away from organic matter

- Protective Equipment: Use chemical-resistant gloves, goggles, and acid-resistant clothing. Ensure proper ventilation when handling.

Market and supply

- Packaging: Available in HDPE or fluoropolymer containers, typically in 2.5 liters, 25 liters, or bulk packaging, for industrial use

- Regulations: Meets SEMI C7 standards for semiconductor applications and other high-purity industry requirements